US Manufacturing: Tracking 5% Growth by Mid-2025

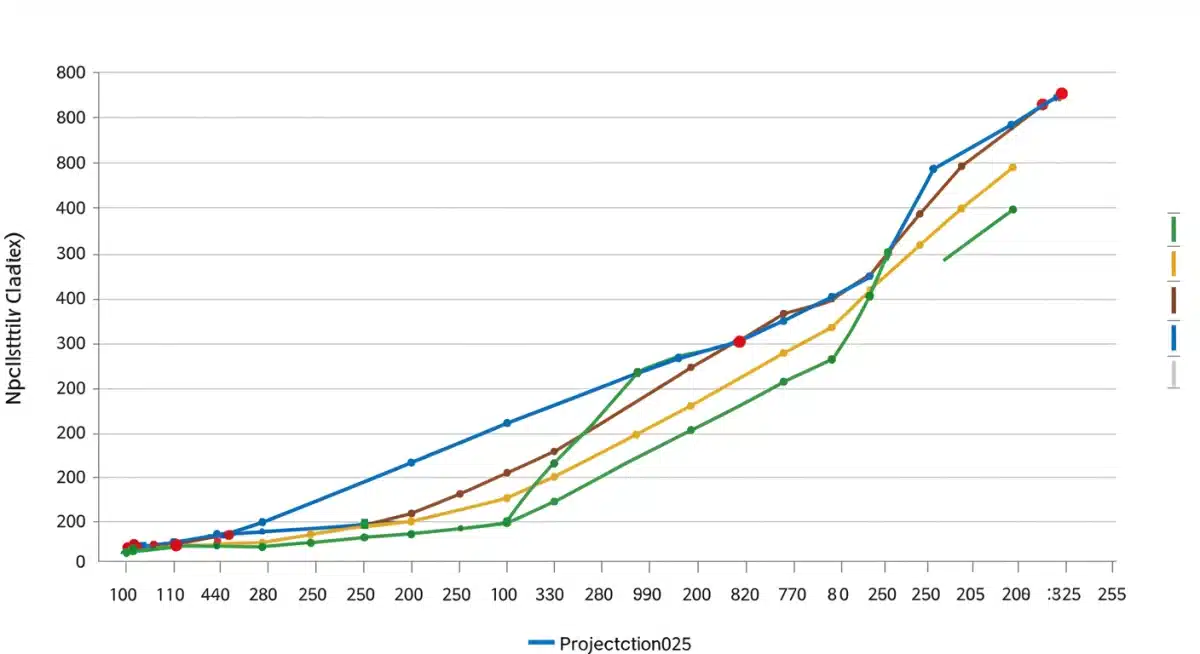

The US manufacturing sector is projected to achieve a 5% growth in industrial production by mid-2025, driven by reshoring initiatives and significant technological investments.

The landscape of American manufacturing is undergoing a profound transformation, signaling a new era of growth and innovation. As we look towards mid-2025, projections indicate a remarkable US industrial production growth of 5%, a figure that underscores a robust resurgence in the sector. This isn’t merely an optimistic forecast; it’s a reflection of strategic shifts, policy support, and an unwavering commitment to domestic production that promises to reshape the nation’s economic future.

Understanding the Drivers of US Industrial Production Growth

The anticipated 5% growth in US industrial production by mid-2025 is not a standalone phenomenon but the culmination of several powerful economic and geopolitical forces. These drivers are creating a fertile ground for manufacturing expansion, pushing companies to invest more domestically and innovate at an accelerated pace.

One of the primary catalysts is the ongoing push for reshoring and nearshoring. Geopolitical tensions and supply chain vulnerabilities exposed during recent global events have prompted many American companies to reconsider their offshore manufacturing strategies. Bringing production back closer to home reduces lead times, enhances control over quality, and mitigates risks associated with international logistics. This strategic pivot is injecting significant capital and job creation back into the US economy.

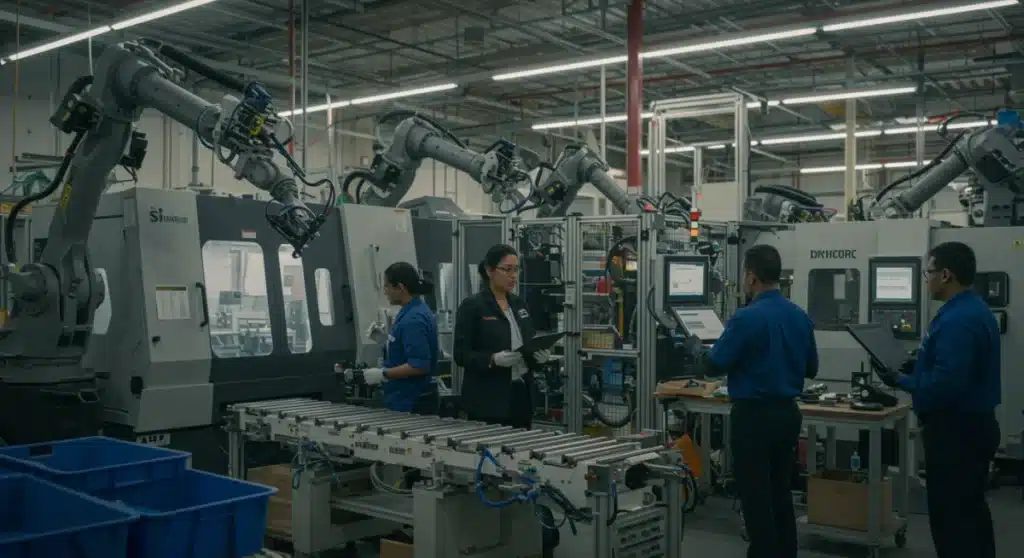

Technological Advancements and Automation

The integration of advanced technologies is fundamentally transforming manufacturing processes. Automation, artificial intelligence (AI), and the Industrial Internet of Things (IIoT) are not just buzzwords; they are becoming integral components of modern factories. These innovations increase efficiency, reduce operational costs, and enable higher precision in production.

- Robotics: Enhanced speed and accuracy in assembly and material handling.

- AI-driven Analytics: Predictive maintenance and optimized production schedules.

- 3D Printing: Rapid prototyping and custom part manufacturing.

- Digital Twins: Virtual models for process optimization and fault detection.

Moreover, government policies and incentives are playing a crucial role in fostering this growth. Legislation aimed at boosting domestic manufacturing, such as tax credits for R&D and investments in advanced production facilities, provides a strong financial impetus for companies to expand. These policies create a supportive environment, encouraging both established industries and emerging sectors to thrive within US borders. The confluence of these factors paints a clear picture of a sector poised for sustained expansion and innovation, driving overall economic prosperity.

Reshoring and Supply Chain Resilience: A New Paradigm

The concept of reshoring, once a niche topic, has moved to the forefront of corporate strategy, becoming a significant contributor to the projected US industrial production growth. Businesses are prioritizing resilience over cost arbitrage, understanding that a robust and localized supply chain is essential for long-term stability and competitiveness. This shift is not just about bringing jobs back; it’s about building a more secure economic foundation.

The vulnerabilities exposed during the pandemic, from shortages of critical goods to disruptions in global shipping, served as a stark wake-up call for many industries. Companies realized that relying heavily on distant suppliers, while potentially cheaper in the short term, carried unacceptable levels of risk. This realization has spurred a deliberate movement to diversify supply chains and, critically, to bring essential manufacturing capabilities back to American soil.

Strategic Investments in Domestic Capacity

To facilitate reshoring, significant capital is being channeled into developing and upgrading domestic manufacturing infrastructure. This includes investments in new factories, state-of-the-art machinery, and the training of a skilled workforce capable of operating these advanced systems. Industries such as semiconductors, pharmaceuticals, and critical minerals are leading this charge, recognizing their strategic importance to national security and economic independence.

- Semiconductor Manufacturing: Billions invested to establish new fabrication plants, reducing reliance on overseas production.

- Pharmaceuticals: Efforts to onshore active pharmaceutical ingredient (API) production to ensure drug supply security.

- Electric Vehicles (EVs): Expansion of battery and EV component manufacturing within the US to support the growing market.

The impact of this reshoring trend extends beyond individual companies; it strengthens entire ecosystems. Local suppliers, logistics providers, and service industries all benefit from increased domestic manufacturing activity. This creates a ripple effect, generating more jobs, stimulating regional economies, and fostering a virtuous cycle of growth. By mid-2025, the tangible results of these reshoring efforts will be a major component of the overall expansion in US industrial production, making the economy more resilient and self-sufficient.

Technological Innovation Fueling Manufacturing Expansion

Technological innovation stands as a cornerstone of the projected US industrial production growth, acting as a force multiplier for efficiency, quality, and competitiveness. The integration of cutting-edge technologies is not merely an option but a necessity for manufacturers seeking to thrive in a rapidly evolving global market. These advancements are enabling American factories to produce goods more intelligently and sustainably.

The advent of Industry 4.0 concepts has revolutionized how manufacturing operates. Smart factories, characterized by interconnected systems, real-time data analysis, and autonomous processes, are becoming the norm. This paradigm shift allows for greater flexibility in production, enabling manufacturers to respond swiftly to changing market demands and customize products with unprecedented ease. The result is a more agile and responsive industrial base.

The Role of Artificial Intelligence and Data Analytics

Artificial intelligence (AI) and advanced data analytics are at the heart of this technological revolution. AI-powered systems can analyze vast amounts of production data to identify bottlenecks, predict equipment failures, and optimize energy consumption. This leads to substantial cost savings and improved operational efficiency, directly contributing to increased output and profitability.

- Predictive Maintenance: AI algorithms forecast machinery malfunctions, minimizing downtime.

- Quality Control: Computer vision systems detect defects with higher accuracy than human inspection.

- Supply Chain Optimization: AI models enhance inventory management and logistics planning.

Furthermore, the continuous development of advanced materials is opening new avenues for product design and performance. Innovations in composites, nanomaterials, and smart materials are enabling the creation of lighter, stronger, and more functional products across various sectors, from aerospace to consumer electronics. This material science progress often requires sophisticated manufacturing techniques, further driving investment in advanced production capabilities within the US.

The synergy between technological innovation and manufacturing processes is creating a powerful engine for economic expansion. By embracing these advancements, US manufacturers are not only increasing their output but also enhancing their global competitive edge, solidifying the path toward the projected 5% growth in industrial production.

Policy Support and Investment Incentives for Growth

Government policy plays an indispensable role in shaping the economic landscape, and its support for manufacturing is a critical factor in the projected US industrial production growth. Strategic legislative actions and investment incentives are designed to foster a conducive environment for domestic industry, encouraging businesses to expand and innovate within the United States.

Recent legislative packages have specifically targeted key sectors, providing substantial financial backing for companies willing to invest in US-based production. These incentives often come in the form of tax breaks, grants, and subsidies for research and development, workforce training, and the construction of new facilities. The aim is to reduce the initial financial burden and long-term operating costs for manufacturers, making domestic production more attractive compared to offshore alternatives.

Key Government Initiatives

Several landmark initiatives are currently in effect, directly impacting manufacturing investment and expansion. These policies are carefully crafted to address specific national priorities, such as technological independence and energy security.

- CHIPS and Science Act: Provides over $50 billion to boost domestic semiconductor research, development, and manufacturing.

- Inflation Reduction Act (IRA): Offers tax credits and incentives for clean energy manufacturing, including electric vehicles, batteries, and renewable energy components.

- Infrastructure Investment and Jobs Act: Allocates significant funding for improving roads, bridges, and broadband, which indirectly supports manufacturing by enhancing logistics and connectivity.

Beyond direct financial support, the government is also focused on regulatory streamlining. Efforts to reduce bureaucratic hurdles and accelerate permitting processes for new industrial projects can significantly cut down on lead times and overall project costs. This administrative efficiency is just as valuable as financial incentives, as it allows companies to bring new production capacities online more quickly.

The combination of robust financial incentives and a more streamlined regulatory environment creates a powerful impetus for manufacturers. These policies not only attract new investments but also encourage existing businesses to modernize and expand their operations, thereby directly contributing to the anticipated surge in US industrial production. This concerted effort underscores a national commitment to revitalizing the manufacturing sector.

Workforce Development and Skill Adaptation

Achieving the projected US industrial production growth hinges significantly on the availability of a skilled and adaptable workforce. As manufacturing evolves with advanced technologies, the demand for new and specialized skills intensifies. Investing in workforce development is therefore crucial to ensure that American workers are equipped to meet the demands of modern factories and innovative production processes.

The shift towards automation and digital manufacturing requires a different set of competencies than traditional industrial roles. There’s a growing need for workers proficient in robotics, data analytics, cybersecurity, and advanced materials science. Bridging this skills gap is a priority for both industry and educational institutions, requiring collaborative efforts to design relevant training programs.

Educational and Training Initiatives

Various initiatives are underway to upskill and reskill the American workforce. These programs range from vocational training and community college courses to apprenticeships and industry-led certifications. The goal is to create a pipeline of talent that can seamlessly transition into high-tech manufacturing roles.

- Apprenticeship Programs: Combining on-the-job training with classroom instruction for practical skills.

- Community College Partnerships: Developing curricula tailored to local industry needs, focusing on automation and digital tools.

- STEM Education: Promoting science, technology, engineering, and mathematics education from an early age to build foundational skills.

- Industry Certifications: Standardized training ensuring workers meet specific industry requirements for advanced machinery.

Furthermore, companies themselves are investing in internal training programs to upgrade the skills of their existing employees. This proactive approach helps retain experienced workers while integrating them into new technological frameworks. By fostering a culture of continuous learning, manufacturers can ensure that their human capital remains a competitive asset.

The success of these workforce development efforts is paramount. A well-trained and adaptable labor force not only supports the immediate growth targets but also ensures the long-term sustainability and competitiveness of US manufacturing. Without a skilled workforce, even the most advanced factories cannot operate at their full potential, making this a critical area for sustained industrial expansion.

Economic Impact and Future Outlook

The projected 5% US industrial production growth by mid-2025 carries substantial economic implications, signaling a robust revitalization of a sector critical to national prosperity. This expansion is expected to generate a wide array of benefits, from job creation and increased wages to enhanced economic stability and global competitiveness. The ripple effects will be felt across various segments of the US economy.

One of the most immediate impacts will be on employment. A growing manufacturing sector translates directly into new jobs, not just on factory floors but also in supporting industries such as logistics, engineering, research and development, and raw material supply. These jobs often offer competitive wages and benefits, contributing to increased consumer spending and overall economic activity.

Broader Economic Benefits

Beyond direct employment, the manufacturing resurgence strengthens the entire economic ecosystem. It fosters innovation, encourages capital investment, and improves the balance of trade by reducing reliance on imported goods. A stronger domestic manufacturing base also provides greater economic resilience against global disruptions.

- GDP Contribution: Increased industrial output directly boosts Gross Domestic Product.

- Innovation Ecosystem: Manufacturing growth stimulates R&D, leading to new patents and technologies.

- Regional Development: New factories and expansions bring economic vitality to specific regions and communities.

- National Security: Reduced dependence on foreign supply chains for critical goods enhances national security.

Looking ahead, the momentum generated by this growth is expected to sustain itself, provided that strategic investments in technology, workforce, and infrastructure continue. The focus on high-tech manufacturing, such as semiconductors and advanced materials, positions the US at the forefront of future industrial trends. This strategic positioning ensures that American manufacturing remains globally competitive and adaptable to emerging challenges.

The future outlook for US industrial production is optimistic, with the groundwork laid for sustained growth beyond mid-2025. This resurgence represents a significant step towards a more self-reliant, innovative, and prosperous American economy, demonstrating the enduring importance of a strong manufacturing sector.

| Key Aspect | Brief Description |

|---|---|

| Projected Growth | US industrial production is forecast to grow by 5% by mid-2025. |

| Key Drivers | Reshoring, technological innovation, and supportive government policies are central. |

| Economic Impact | Job creation, increased GDP contribution, and enhanced supply chain resilience. |

| Challenges | Workforce skill gaps and global competition remain significant hurdles. |

Frequently Asked Questions About US Manufacturing Growth

The growth is primarily driven by a combination of factors including increased reshoring efforts, significant investments in advanced manufacturing technologies like AI and automation, and supportive government policies aimed at boosting domestic production and supply chain resilience.

Reshoring brings manufacturing operations back to the US, reducing reliance on foreign supply chains and mitigating geopolitical risks. This directly increases domestic production capacity, creates jobs, and stimulates local economies, contributing significantly to overall industrial output.

Advanced technologies such as robotics, AI, and the Industrial Internet of Things (IIoT) are enhancing efficiency, reducing costs, and improving product quality. These innovations make US manufacturing more competitive globally and enable faster adaptation to market demands.

Yes, significant legislation like the CHIPS and Science Act and the Inflation Reduction Act provide substantial incentives, tax credits, and funding for domestic manufacturing in critical sectors such as semiconductors, clean energy, and electric vehicles, fostering investment and expansion.

The growth is expected to create numerous jobs, both directly in manufacturing and in supporting industries. It will also boost the GDP, foster innovation, enhance national security through stronger supply chains, and contribute to regional economic development across the US.

Conclusion

The anticipated 5% growth in US industrial production by mid-2025 is a testament to a concerted national effort to revitalize its manufacturing sector. Driven by a powerful combination of strategic reshoring, rapid technological adoption, robust government support, and a renewed focus on workforce development, this resurgence promises significant economic benefits. As the nation moves forward, sustained commitment to these pillars will be crucial in solidifying America’s position as a global manufacturing powerhouse, fostering innovation, creating jobs, and ensuring a more resilient and prosperous future for all.