The Future of US Manufacturing: Automation and Reshoring Impact

The future of US manufacturing hinges on automation and reshoring, impacting job creation, economic growth, and global competitiveness.

The US manufacturing sector is undergoing a significant transformation, driven by advancements in automation technologies and a renewed focus on reshoring initiatives. Understanding the interplay between these two trends is crucial for navigating the evolving landscape of the American economy. Join us as we explore the future of US manufacturing: analyzing the impact of automation and reshoring.

The Rise of Automation in US Manufacturing

Automation is rapidly changing the face of US manufacturing, bringing increased efficiency and productivity to companies across the nation. From robotics to artificial intelligence (AI), these technologies are reshaping traditional processes and improving overall operational capabilities.

The adoption of automation technologies enables manufacturers to optimize production, reduce costs, and enhance the quality of their products. As companies invest in these technologies, they become more competitive in the global market and contribute to the growth of the US economy.

Key Automation Technologies Driving Change

Several key technologies are at the forefront of the automation revolution in US manufacturing. These include:

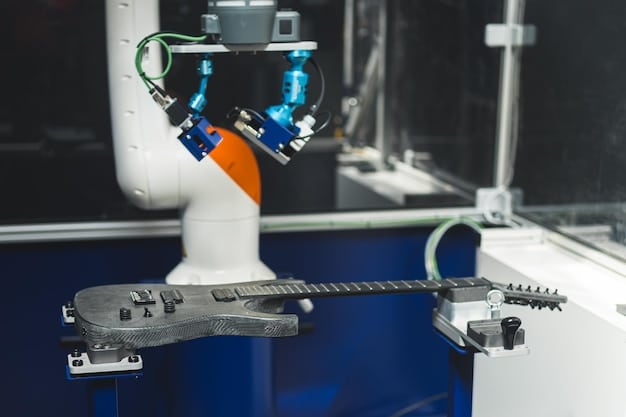

- Robotics: Automated robots perform repetitive and complex tasks, increasing efficiency and reducing labor costs.

- Artificial Intelligence (AI): AI algorithms optimize processes, improve decision-making, and enable predictive maintenance.

- Internet of Things (IoT): IoT devices connect machines and systems, providing real-time data and enabling remote monitoring and control.

- 3D Printing: Additive manufacturing technologies allow for rapid prototyping and the creation of customized products.

These technologies are not just theoretical concepts; they are actively being implemented in factories across the US, revolutionizing how goods are produced.

The convergence of these technologies is creating smart factories that are more efficient, flexible, and resilient than ever before. By embracing automation, US manufacturers can unlock new levels of productivity and competitiveness.

The Reshoring Trend: Bringing Manufacturing Back Home

Reshoring, the practice of bringing manufacturing operations back to the US, has gained momentum in recent years. This trend is driven by a combination of factors, including rising labor costs overseas, concerns about supply chain disruptions, and a desire to support American jobs.

As companies re-evaluate their global manufacturing strategies, many are finding that the benefits of producing goods in the US outweigh the costs. Reshoring initiatives are not only revitalizing the American manufacturing sector but also creating new opportunities for economic growth and job creation.

Factors Driving the Reshoring Trend

Several factors are contributing to the resurgence of US manufacturing. These include:

- Rising Overseas Labor Costs: As wages increase in countries like China, the cost advantage of offshore manufacturing diminishes.

- Supply Chain Resilience: Companies are seeking to reduce their reliance on global supply chains to mitigate risks associated with disruptions.

- Government Incentives: Federal and state governments are offering tax breaks and other incentives to encourage companies to reshore manufacturing operations.

- Made in USA Branding: Consumers are increasingly willing to pay a premium for products that are made in the US, reflecting a desire to support local businesses and jobs.

These factors, coupled with advancements in automation technologies, make reshoring an attractive option for many companies.

The reshoring trend is not just a passing fad; it represents a fundamental shift in how companies view global manufacturing. By bringing production back to the US, companies can gain greater control over their supply chains, improve product quality, and support the American economy.

The Impact of Automation on the Workforce

The increasing adoption of automation technologies has raised concerns about its potential impact on the workforce. While automation can lead to job displacement in certain sectors, it also creates new opportunities for skilled workers.

As machines take over repetitive and manual tasks, human workers can focus on more complex and creative roles. To prepare for the future of work, it is essential to invest in education and training programs that equip individuals with the skills needed to thrive in an automated environment.

Retraining and Upskilling Initiatives

To mitigate the potential negative impacts of automation on the workforce, several initiatives are underway to retrain and upskill workers. These include:

- Community College Programs: Community colleges are offering courses and programs focused on advanced manufacturing technologies, such as robotics and AI.

- Apprenticeships: Apprenticeship programs provide on-the-job training and mentorship, enabling workers to develop valuable skills.

- Online Learning Platforms: Online platforms offer flexible and affordable learning opportunities, allowing individuals to acquire new skills at their own pace.

By investing in these initiatives, policymakers and businesses can ensure that the workforce is prepared for the challenges and opportunities of the automated economy.

The key is to view automation not as a threat, but as an opportunity to create a more skilled and productive workforce. By embracing lifelong learning and investing in education, individuals can adapt to the changing demands of the labor market.

Government Policies and Support for US Manufacturing

Government policies play a crucial role in shaping the future of US manufacturing. By implementing policies that support innovation, investment, and workforce development, the government can create a favorable environment for manufacturers to thrive.

Incentives, research and development funding, and trade policies are crucial aspects to focus on, supporting the growth and revitalization of the US manufacturing sector.

Key Government Initiatives

Several government initiatives are aimed at supporting US manufacturing. These include:

- Tax Incentives: Tax credits and deductions encourage companies to invest in new equipment and expand their operations in the US.

- Research and Development Funding: Government funding supports research and development efforts, fostering innovation and the development of new technologies.

- Trade Policies: Trade agreements and policies aim to level the playing field for US manufacturers in the global market.

By implementing these policies, the government can create a more competitive and sustainable manufacturing ecosystem in the US.

The Role of Innovation in Driving Manufacturing Growth

Innovation is the lifeblood of the US manufacturing sector. By investing in research and development, manufacturers can create new products, improve processes, and gain a competitive edge in the global market.

From advanced materials to digital technologies, innovation is transforming the way goods are designed, produced, and delivered. Companies that embrace innovation are more likely to thrive in the face of technological disruption and changing consumer preferences.

Fostering a Culture of Innovation

To foster a culture of innovation, companies need to:

- Invest in Research and Development: Allocate resources to explore new technologies and develop innovative products and processes.

- Encourage Collaboration: Foster collaboration between different departments and teams to generate new ideas and solve complex problems.

- Embrace Risk-Taking: Encourage employees to take risks and experiment with new approaches, even if they don’t always succeed.

By creating a culture that values innovation, companies can unlock their full potential and drive long-term growth.

Sustainability in US Manufacturing

Sustainability is becoming an increasingly important consideration for US manufacturers. As consumers become more environmentally conscious, companies are under pressure to reduce their environmental impact and adopt more sustainable practices.

Embracing sustainability helps improve efficiency and attract eco-conscious customers, who are increasingly valuing environmentally responsible products and brands.

Sustainable Manufacturing Practices

Sustainable manufacturing practices that can be adopted include:

- Reducing Waste: Minimizing waste generation through efficient processes and recycling programs.

- Conserving Energy: Using energy-efficient equipment and optimizing energy consumption.

- Using Sustainable Material: Sourcing sustainable materials and reducing reliance on finite resources.

By embracing these practices, manufacturers can reduce their environmental footprint, improve their bottom line, and enhance their brand reputation.

In conclusion, the US manufacturing sector is poised for a period of transformation, driven by automation and reshoring trends. While there are challenges to overcome, the opportunities for growth and innovation are immense. By embracing technology, investing in workforce development, and prioritizing sustainability, US manufacturers can secure a bright future for themselves and the American economy.

| Key Point | Brief Description |

|---|---|

| 🤖 Automation | Increasing efficiency with robotics and AI in manufacturing processes. |

| 🏡 Reshoring | Bringing manufacturing back to the US to boost local economies. |

| 🛠️ Workforce Training | Upskilling programs to prepare workers for new manufacturing roles. |

| 🌿 Sustainability | Adopting eco-friendly practices to reduce environmental impact. |

FAQ

▼

Automation is revolutionizing US manufacturing by enhancing efficiency, reducing costs, and improving product quality through technologies like robotics and AI.

▼

The reshoring trend is fueled by rising overseas labor costs, supply chain vulnerabilities, government incentives, and a preference for “Made in USA” products.

▼

The workforce can adapt by participating in retraining and upskilling programs that focus on advanced manufacturing skills, preparing them for new roles created by automation.

▼

The government supports manufacturing through tax incentives, R&D funding, and trade policies that aim to foster innovation and create a level playing field for US manufacturers.

▼

Sustainability is crucial as it helps manufacturers reduce their environmental impact, improve efficiency, attract eco-conscious consumers, and enhance brand reputation.

Conclusion

In summary, the US manufacturing sector faces a transformative future shaped by both automation and reshoring. Overcoming challenges and embracing the opportunities presented by technology, workforce development, and sustainability will be vital for securing a prosperous future for American manufacturers and the US economy.